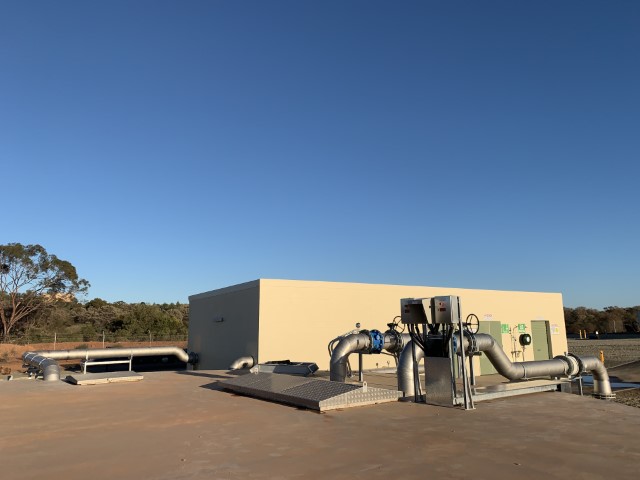

The Cobar WTP is an 8 MLD plant designed and constructed to cope with high turbidity, high colour water pumped 130km to Cobar water storages from the Nyngan Weir Pool, which in turn is transferred via a 73km open channel from the Macquarie River.

The key process units of the plant are comprised of dual train lamella clarifiers – LCW bespoke custom designed and fabricated to suit high turbidity expectations in raw water quality (3-400NTU; 10-1000 AC HU expected), followed by a Four train Dissolved Air Flotation and Filtration (DAFF) system housed in concrete water retaining structure.

These processes are supported by a range of chemical dosing systems to support treatment of colour and dissolved organics (PAC dosing, KMnO4 dosing) pH correction (soda ash dosing), coagulation and flocculation (ACH and polymer dosing), disinfection (UV + Gaseous Chlorine dosing), and facility for future dosing of fluoride. LC Water also designed and constructed the sludge lagoon systems to handle the DAFF waste stream.

The ELEC/PLC/SCADA work was subcontracted by LCWater to EDC, a team with whom we have worked for many years, and whose work was project managed by LCWater throughout. LC Water also fully commissioned the plant ourselves, developing all management plans, functional descriptions, and ITPs ourselves.

The works were a success because the plant operates as specified, and is currently treating the incoming water defined above to ADWG specifications.

For a link to an account of the opening ceremony, click here.

Value: $9.5M